The EV Career Pathways guide provides pathways for those interested in transitioning from traditional manufacturing or internal combustion engine vehicle (ICE-V) production jobs to electric vehicle (EV) careers with transferable skillsets. With such a strong automotive manufacturing landscape, Windsor-Essex is the ideal region for those currently employed in traditional automotive manufacturing jobs to transition into EV careers of the future.

The Windsor-Essex region is historically known for its strong presence in the automotive industry. It is home to major automakers and auto parts suppliers, making it a significant hub for the automotive industry in Canada and North America. A global shift to the electrification of vehicles is bringing changes to the region’s automotive industry, including talent that will be employed to produce electric vehicles (EVs). Windsor-Essex has recently experienced rapid growth in its EV sector, fuelled by large investments made by companies and organizations interested in capitalizing on the region’s historical automotive industry strength and other strategic advantages.

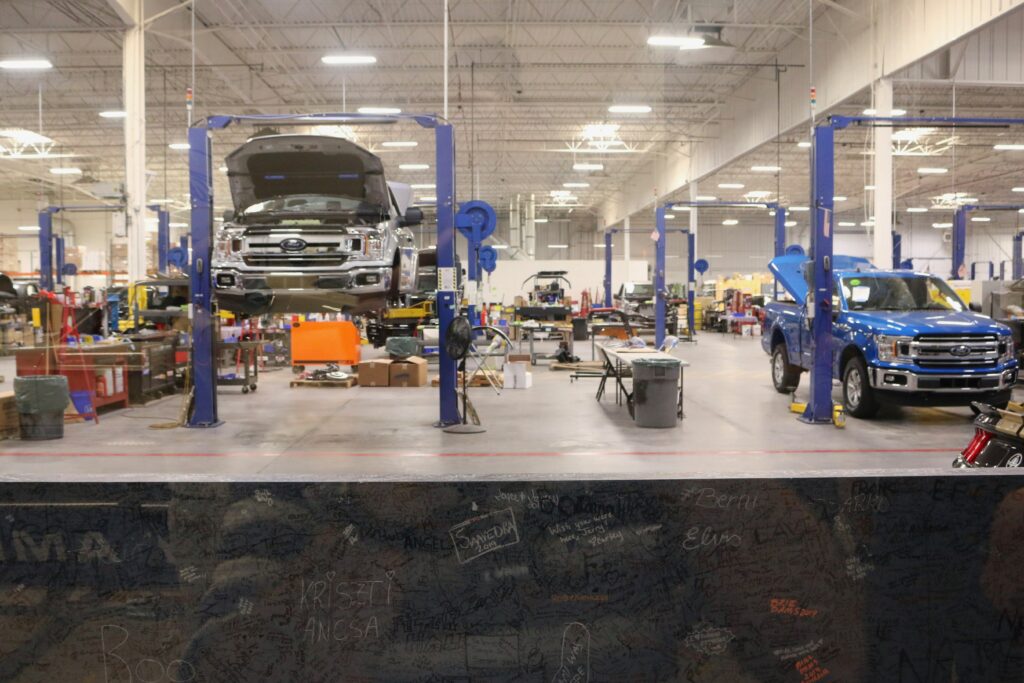

The region now houses the NextStar Energy battery plant, a joint venture between Stellantis and LG Energy, which will be fully operational by 2025 and directly employ 2,500 workers. The battery plant has already begun its initial hiring phase, seeking approximately 130 professionals who will lead the plant’s future workforce in the production of EV batteries.[1] The plant will be one of the largest EV battery plants in the world and has helped to encourage a stream of other EV-related investments, including Dongshin Motech’s planned $60-million facility to manufacture battery casings (expected to create 300 new jobs)[2] and another plant that will provide insulation for the batteries. There are also ongoing negotiations with two other companies to locate power train and electrolyte production facilities to support the region’s EV production and supply chain.[3] Retooling of the Stellantis Windsor Assembly plant is also underway to build platforms for multiple battery-electric or hybrid vehicles, slated to begin production in 2024.[4] On top of these new investments and changes, many existing tier one, two, and three automotive suppliers have pivoted toward the production of EV parts.

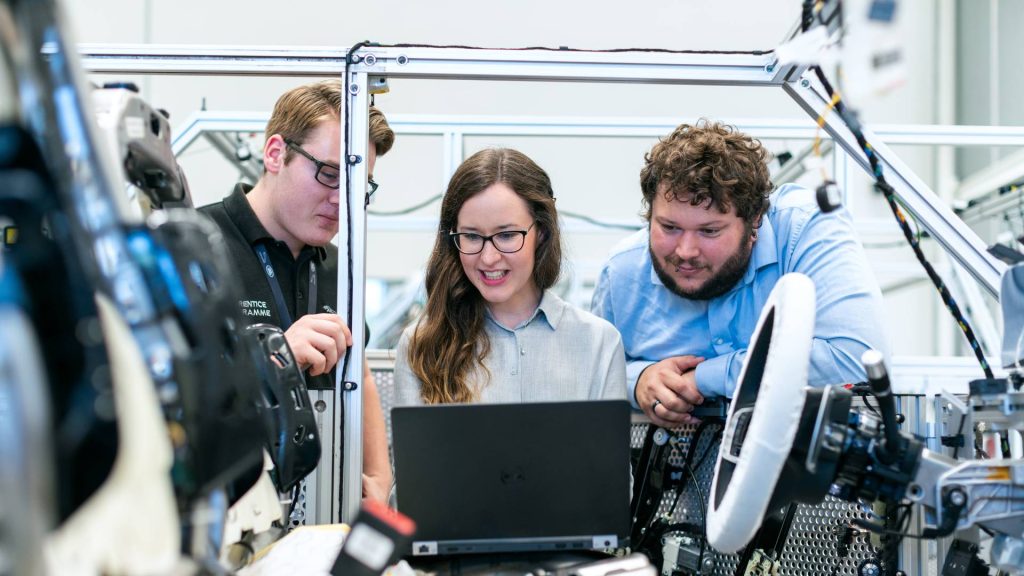

Windsor-Essex’s EV sector growth is changing the automotive occupational landscape. As a result of the ongoing electrification of vehicles, new jobs and careers are being created in a rapidly growing EV sector. Many of these jobs are different than those that have existed for decades in an automotive industry that has been dominated by the production of ICE-Vs. In-demand skillsets are evolving for new EV sector jobs. To help supply a talent pipeline for EV sector growth, the region of Windsor-Essex can engage in multiple initiatives. One of these initiatives could be to create a talent attraction and retention strategy to attract trained professionals to the region to fill jobs available in the sector. The region can also work in partnership with educational institutions to effectively promote the EV sector to our future workforce generation. Getting students interested in EV sector roles can help ensure a talent pipeline for the foreseeable future. However, one of the most important initiatives the region can engage in is to ensure how individuals in the region with an automotive background are properly informed about how to transition to EV sector careers.

The automotive sector in Windsor-Essex currently employs approximately 24,000 workers. Over 60% of these workers are employed in vehicle assembly and parts manufacturing roles, representing a potentially substantial workforce with highly transferable skillsets to the growing EV sector. This includes workers with backgrounds and experience in automotive engineering, parts assembly, quality insurance, and many other roles highly applicable to the EV sector. The remaining 40% of workers are employed in other automotive sector-associated activities.[5] The Windsor-Essex region is home to Canada’s largest automotive cluster, with a concentration of companies 120% greater than anywhere else in Canada. The region also boasts an automobility cluster more than 50% larger than any other location in Canada. More than 90 auto parts manufacturers, including two OEMs – Stellantis and Ford – call Windsor-Essex home.[6]

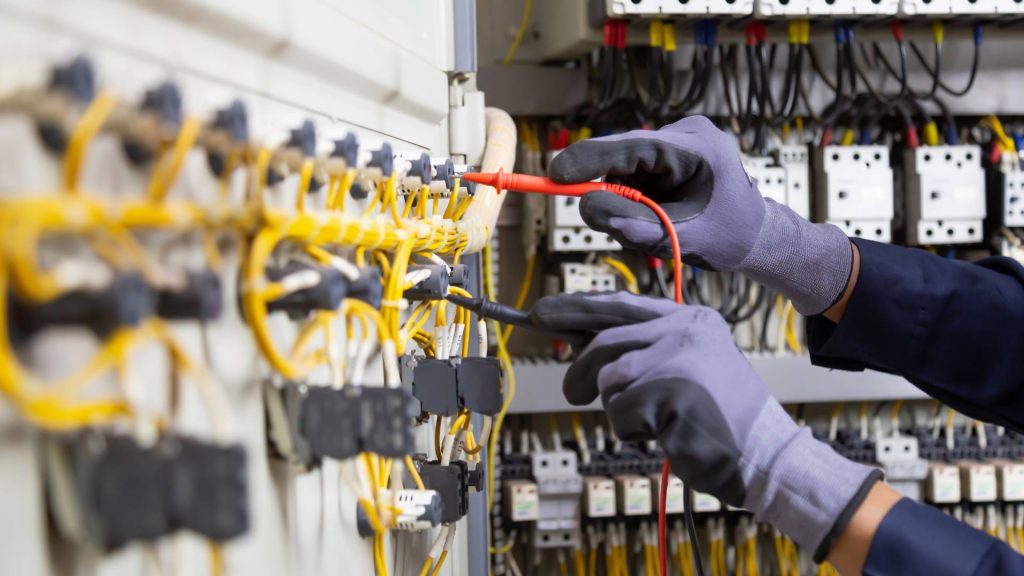

With such a strong automotive industry, it is crucial for the region’s labour force that possess an automotive background to be able to transition to the new jobs that are becoming available. This includes both individuals who are currently employed in ICE-V production roles, and unemployed individuals with an automotive background or experience. There is great potential for individuals with ICE-V and other manufacturing backgrounds and experience to transition to EV sector careers with some form of upskilling or training. To fully prepare the region’s workforce, it is important to identify how individuals who possess ICE-V and other manufacturing experience and knowledge can effectively transition their skills to the EV sector. Individuals interested in EV sector careers must know what transferable skills they possess, as well as what type of upskilling they may need to effectively transition their careers. For example, the CEO of the NextStar Energy battery plant recently mentioned that traditional assembly of battery parts will now be completed by equipment and machinery. This means that the workers on the production floor will need to be able to install, set parameters, maintain, and troubleshoot the equipment and machinery. These workers will require a comprehensive knowledge of the machine’s hardware and software.[7] Securing talent for the EV sector in Windsor-Essex is critical for continued growth. EV supply chain companies who wish to locate their operations and invest in the region will need to be reassured they have available talent to staff their facilities.

Hiring for the EV sector in Windsor-Essex has already begun. Many of the job postings we are seeing now are part of initial hiring phases from companies that have located in the region. As their operations continue to grow toward full capacity, hiring numbers are expected to increase. Predictions show that recent investments into the region’s EV sector will create over 3,000 direct jobs. More companies are expected to locate in the Windsor-Essex region to capitalize on its growing EV sector, which will further increase hiring demand as they approach full capacity and become fully operational. Preparation of an effective EV workforce must happen now to keep up the pace with EV sector investments and growth. Windsor-Essex needs to capitalize on current opportunity to modernize, train, and upskill its workforce to ensure the automotive sector maintains its strength moving forward into the age of EV production.

To support a growing EV sector in Windsor-Essex, this report will focus on how to transition into EV sector career opportunities for individuals with an automotive background. The information will highlight in-demand transferable skills for those interested in making a transition to the EV sector. The report will also identify upskilling or training that may be required to enter EV sector roles. This report will also identify training gaps for educational institutions and other service providers to consider for developing and modifying programming and training options. Identification of EV sector careers, transferable skills, upskilling, and education and training gaps will improve community and partner knowledge about how to better prepare Windsor-Essex’s workforce for EV sector careers. This initiative will help support a robust talent pipeline for the region’s EV sector, as well as alleviate brain drain effects from other sectors that will experience losses of employees transitioning to EV sector roles. Educational institutions and training service providers will also be able to act on the provided information to make improved decisions about curriculum and programming.

[1] Rusty Thomson. “First phase of hiring beginning for EV battery plant in Windsor.” AM800, July 31, 2023.

[2] Rich Garton. “Windsor lands $60M electric vehicle supply chain investment.” CTV News Windsor, June 3, 2022.

[3] Dave Waddell. “Windsor lands another big EV auto supply chain company.” Windsor Star, July 24, 2023.

[4] “Stellantis details production changes at its Brampton and Windsor assembly plants.” CBC Windsor, June 3, 2022.

[5] “Windsor’s Labour Market Forecast.” FOCAL Initiative, June 2020.

[6] “Canada’s automotive capital Windsor-Essex.” Perspective, March 19, 2021.

[7] Dave Waddell. “NextStar Energy EV battery plant begins big hiring spree.” Windsor Star, July 31, 2023.

To provide a comprehensive overview of potential career opportunities within the EV sector, this guide will categorize roles into five distinct domains. These categories will serve as groupings to identify and understand various pathways available in Windsor-Essex’s burgeoning EV sector. Each category will be accompanied by an overview and definitions to facilitate a clearer understanding of the roles encompassed within them.

The following are the five major categories:

- Manufacturing

- EV Manufacturing refers to the process of producing EVs on a large scale, involving the assembly of various components and subsystems to create a fully functional EV.

- Maintenance

- EV Maintenance refers to the regular upkeep, servicing, and repairs required to keep EVs in optimal operating condition.

- Scientific Research

- EV Scientific Research refers to the systematic investigation and study conducted by scientists, researchers, and experts in various fields to advance the knowledge and understanding of EVs.

- Design and Development

- EV Design and Development refers to the process of creating and refining EVs.

- Infrastructure

- EV Infrastructure refers to the network of charging stations, support systems, and associated technologies that enable the charging and operation of EVs.

Manufacturing

EV manufacturing refers to the process of producing EVs on a large scale, involving the assembly of various components and subsystems to create a fully functional EV. It encompasses the entire production cycle, from sourcing raw materials to the final assembly of the vehicle. EV manufacturing involves a combination of traditional automotive manufacturing processes and specialized procedures specific to EVs. EV manufacturing is a complex and highly specialized process that requires expertise in EV technology, automotive manufacturing techniques, and quality control procedures.

The following transitions to EV careers in manufacturing can be made by those with automotive knowledge and experience. Each of the below career pathways represents a traditional manufacturing or an ICE-V production job transitioning (➤) to multiple potential EV careers with transferable skillsets.

ICE-V Production Job Description

Assembly Line Worker – 94200 (NOC 2021) | 9522 (NOC 2016):

- Assembly Line Workers in the manufacturing stage of ICE-V production help put cars together in a factory setting. They work on a moving line where each person has a specific task. Their job is to install parts like engines, doors, and seats onto a vehicle’s frame.

Transferable Skills

- EV Assembly Technician: Assembly, quality control inspection, tool operation, mechanical aptitude, teamwork, attention to detail, adherence to safety protocols, process efficiency, adaptability, problem-solving skills, and familiarity with manufacturing regulations and standards.

- Battery Pack Assembly Operator: Component assembly, quality control inspection, tool operation, mechanical aptitude, teamwork, attention to detail, adherence to safety protocols, process efficiency, adaptability, problem-solving skills, and familiarity with manufacturing regulations and standards.

- EV Quality Control Inspector: Component assembly, quality control inspection, tool operation, mechanical aptitude, attention to detail, adherence to safety protocols, teamwork, process efficiency, adaptability, problem-solving skills, familiarity with manufacturing regulations and standards, and an understanding of production processes.

Upskilling/Training

- EV Assembly Technician: Electric powertrain assembly, high-voltage system handling, battery installation procedures, and EV safety protocols, while training in areas such as battery pack integration, electric motor mounting, and diagnostics.

- Battery Pack Assembly Operator: Battery cell handling, pack assembly procedures, thermal management considerations, and quality control processes, while training in areas such as battery chemistry, safety protocols, and electric powertrain integration.

- EV Quality Control Inspector: Electric powertrain components, battery systems, charging systems, and EV-specific quality control processes, while training in areas such as battery performance testing, electrical system diagnostics, and advanced inspection techniques.

Educational Requirements

- Assembly Line Worker (ICE-V): High school diploma or equivalent education.

- EV Assembly Technician (EV): Diploma in automotive technology or similar education.

- Battery Pack Assembly Operator (EV): High school diploma or equivalent education with on-the-job training.

- EV Quality Control Inspector (EV): High school diploma or equivalent education with on-the-job training.

EV Production Job Descriptions

EV Assembly Technician:

- EV Assembly Technicians help build EVs in a factory setting. They use their skills to put together the different parts that make up the vehicle, like the electric motor, batteries, and other components. These technicians follow instructions and use tools to assemble the parts accurately.

Battery Pack Assembly Operator:

- Battery Pack Assembly Operators help put together the batteries that power EVs. They use their skills to assemble the battery cells, wiring, and other components to create the complete battery pack. These operators follow guidelines and use tools to assemble the parts accurately.

EV Quality Control Inspector:

- EV Quality Control Inspectors check EVs to make sure they are built properly. They use their skills to carefully examine the vehicles and their parts to ensure everything meets high standards. Inspectors use tools and their knowledge to spot any mistakes or problems.

ICE-V Production Job Description

Welder/Fabricator – 72106 (NOC 2021) | 7237 (NOC 2016):

- Welders/Fabricators in the manufacturing stage of ICE-V production use special machines to weld and join pieces of metal together, making them strong and secure. These workers also shape and cut the metal to create parts like frames, doors, and engine components.

Transferable Skills

- Battery Pack Welding Technician: Welding expertise, metal fabrication experience, precision in assembly, tool operation, attention to detail, adherence to safety protocols, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of production processes.

- EV Chassis Welder: Welding expertise, metal fabrication experience, precision in assembly, tool operation, attention to detail, adherence to safety protocols, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of chassis production processes.

- EV Body Welder/Assembler: Welding expertise, metal fabrication experience, precision in assembly, tool operation, attention to detail, adherence to safety protocols, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of body assembly processes.

Upskilling/Training

- Battery Pack Welding Technician: Upskilling requires developing expertise in battery pack assembly techniques, battery cell welding methods, high-voltage safety protocols, and quality assurance processes, while training in areas such as battery pack design, weld inspection standards, and electric powertrain integration.

- EV Chassis Welder: Upskilling involves gaining proficiency in EV chassis design, welding techniques for lightweight materials, battery pack integration considerations, and high-voltage safety protocols, while training in areas such as electric powertrain assembly, chassis structural integrity, and EV-specific welding standards.

- EV Body Welder/Assembler: Upskilling requires developing expertise in EV body construction, welding techniques for lightweight materials, battery placement considerations, and high-voltage safety protocols, while training in areas such as EV body design, structural integrity, and integration of electric powertrain components.

Local training and upskilling opportunities can be found here:

Educational Requirements

- Welder/Fabricator (ICE-V): High school diploma or equivalent education and completion of apprenticeship.

- Battery Pack Welding Technician (EV): Completion of apprenticeship and on-the-job training.

- EV Chassis Welder (EV): Completion of apprenticeship with on-the-job training.

- EV Body Welder/Assembler (EV): Completion of apprenticeship with on-the-job training.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Production Job Descriptions

Battery Pack Welding Technician:

- Battery Pack Welding Technicians help build the batteries that power EVs. They use their skills to join different parts of the battery pack together using a special machine called a welder. These technicians follow specific instructions to make sure the welding is done accurately and securely.

EV Chassis Welder:

- EV Chassis Welders help build the main framework or chassis of EVs. They use their skills to join different metal parts of the chassis together using welding techniques. These welders follow specific instructions and use welding tools to create strong and secure connections.

EV Body Welder/Assembler:

- EV Body Welder/Assemblers put together the different metal parts that form the body of an EV. They use their skills to join these parts using welding techniques and other tools. These welder/assemblers follow specific instructions to ensure the body is well-built and secure.

ICE-V Production Job Description

Machinist – 72100 (NOC 2021) | 7231 (NOC 2016):

- Machinists in the manufacturing stage of ICE-V production work with machines to shape metal parts for cars. They use tools like lathes and mills to carefully cut and shape metal into specific shapes and sizes. These parts might include engine components, gears, and other important pieces.

Transferable Skills

- Electric Motor Manufacturing Technician: Machining expertise, precision tool operation, mechanical component fabrication, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of manufacturing processes.

- Battery Pack Manufacturing Specialist: Machining expertise, precision tool operation, mechanical component fabrication, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of manufacturing processes.

- Charging Infrastructure Manufacturing Technician: Machining expertise, precision tool operation, mechanical component fabrication, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of manufacturing processes.

Upskilling/Training

- Electric Motor Manufacturing Technician: Upskilling involves gaining proficiency in electric motor manufacturing processes, precision assembly techniques, motor winding methods, and high-voltage safety protocols, while training in areas such as electric motor design principles, electromagnetic theory, and integration of electric powertrain components.

- Battery Pack Manufacturing Specialist: Upskilling requires developing expertise in battery pack assembly processes, cell handling procedures, thermal management considerations, and quality control techniques, while training in areas such as battery chemistry, safety protocols, and integration of electric powertrain components.

- Charging Infrastructure Manufacturing Technician: Upskilling involves acquiring proficiency in charging infrastructure components, electrical assembly techniques, smart charging systems, and high-voltage safety protocols, while training in areas such as EV charging station design, communication protocols, and integration of power electronics.

Local training and upskilling opportunities can be found here:

Educational Requirements

- Machinist (ICE-V): High school diploma or equivalent education and completion of apprenticeship.

- Electric Motor Manufacturing Technician (EV): Diploma in electrical engineering technology, manufacturing technology, or related field.

- Battery Pack Manufacturing Specialist (EV): Diploma in electrical engineering technology, manufacturing technology, or related field.

- Charging Infrastructure Manufacturing Technician (EV): Diploma in electrical engineering technology, manufacturing technology, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- St. Clair College – Electrical Engineering Technician

- St. Clair College – Mechanical Engineering Technology – Automotive Product Design

EV Production Job Descriptions

Electric Motor Manufacturing Technician:

- Electric Motor Manufacturing Technicians help build the motors for EVs. They use their skills to assemble the various parts of the electric motor, following specific instructions and guidelines. These technicians work with precision to ensure the motor is put together correctly and functions smoothly.

Battery Pack Manufacturing Specialist:

- Battery Pack Manufacturing Specialists focus on creating the batteries that power EVs. They use their skills to assemble and build the battery packs, which are made up of many smaller battery cells. These specialists follow specific instructions and guidelines to ensure the battery packs are put together accurately and safely.

Charging Infrastructure Manufacturing Technician:

- Charging Infrastructure Manufacturing Technicians help create the charging stations that EVs use to recharge. They use their skills to build and assemble the different components of the charging stations. These technicians follow specific instructions and guidelines to ensure the stations are put together accurately and securely.

ICE-V Production Job Description

Tool and Die Maker – 72101 (NOC 2021) | 7232 (NOC 2016):

- Tool and Die Makers in the manufacturing stage of ICE-V production create specialized tools and molds for making vehicle parts. They design and build tools that are used to cut metal into specific shapes. This job involves skill and careful craftsmanship to create the tools that make the vehicle’s parts just right.

Transferable Skills

- EV Component Tooling Specialist: Tool and die design expertise, precision tool fabrication, machining knowledge, CAD/CAM proficiency, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of tooling processes.

- Charging Infrastructure Manufacturing Toolmaker: Tool and die design expertise, precision tool fabrication, machining knowledge, CAD/CAM proficiency, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, mechanical aptitude, and a strong understanding of manufacturing processes.

Upskilling/Training

- EV Component Tooling Specialist: Upskilling requires developing expertise in electric vehicle component manufacturing processes, precision tooling techniques, materials suited for electric powertrain components, and high-voltage safety protocols, while training in areas such as electric powertrain integration, battery enclosure tooling, and specialized machining for EV components.

- Charging Infrastructure Manufacturing Toolmaker: Upskilling requires developing expertise in charging infrastructure manufacturing processes, electrical component tooling design, smart charging systems, and high-voltage safety protocols, while training in areas such as EV charging station integration, communication interfaces, and specialized tooling for charging infrastructure components.

Educational Requirements

- Tool and Die Maker (ICE-V): High school diploma or equivalent education and completion of apprenticeship.

- EV Component Tooling Specialist (EV): Diploma in mechanical engineering technology, manufacturing technology, or related field.

- Charging Infrastructure Manufacturing Toolmaker (EV): Diploma in manufacturing technology or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- St. Clair College – Electrical Engineering Technician

- St. Clair College – Mechanical Engineering Technician – Industrial

EV Production Job Descriptions

EV Component Tooling Specialist:

- EV Component Tooling Specialists focus on creating the special tools and equipment needed to build the various parts of EVs. They use their skills to design and develop the tools that help shape, cut, and assemble the components of the vehicles. These specialists follow specific instructions and use their expertise to ensure the tools are made accurately and perform effectively.

Charging Infrastructure Manufacturing Toolmaker:

- Charging Infrastructure Toolmakers focus on creating the special tools and equipment needed to build charging stations for EVs. They use their skills to design and develop the tools that help shape, assemble, and maintain the charging infrastructure. These toolmakers follow specific instructions and use their expertise to ensure the tools are made accurately and perform effectively.

ICE-V Production Job Description

Material Handler – 75101 (NOC 2021) | 7452 (NOC 2016):

- Material Handlers in the manufacturing stage of ICE-V production help manage the materials needed to build vehicles. They move and organize things like metal pieces, parts, and tools around factory settings. Material handlers use machines like forklifts to safely transport heavy items. This role involves organization and coordination to ensure materials are ready for vehicle production.

Transferable Skills

- EV Parts Logistics Coordinator: Inventory management, parts handling expertise, supply chain coordination, warehouse operations knowledge, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, organizational aptitude, and a strong understanding of logistics processes.

- Battery Pack Material Handler: Inventory management, parts handling expertise, supply chain coordination, warehouse operations knowledge, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, organizational aptitude, and a strong understanding of logistics processes.

- EV Assembly Line Support Worker: Parts coordination, inventory management, supply chain familiarity, attention to detail, quality control awareness, adaptability, problem-solving skills, teamwork, communication abilities, organizational aptitude, and an understanding of manufacturing processes.

Upskilling/Training

- EV Parts Logistics Coordinator: Upskilling involves acquiring expertise in electric vehicle components, battery modules, charging systems, and high-voltage safety protocols, while training in areas such as EV-specific parts inventory management, supply chain logistics, and sustainable sourcing practices.

- Battery Pack Material Handler: Upskilling requires developing proficiency in battery pack components, cell handling procedures, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, pack assembly processes, and electric powertrain integration.

- EV Assembly Line Support Worker: Upskilling involves gaining proficiency in electric vehicle assembly processes, battery components, high-voltage safety protocols, and EV-specific quality control procedures, while training in areas such as battery pack integration, electric powertrain assembly, and troubleshooting of electric vehicle systems.

Educational Requirements

- Material Handler (ICE-V): High school diploma or equivalent education and on-the-job training.

- EV Parts Logistics Coordinator (EV): Diploma in logistics, supply chain management, business administration, or related field.

- Battery Pack Material Handler (EV): High school diploma or equivalent education and on-the-job training.

- EV Assembly Line Support Worker (EV): High school diploma or equivalent education and on-the-job training.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Production Job Descriptions

EV Parts Logistics Coordinator:

- EV Parts Logistics Coordinators focus on making sure all the necessary parts and components for building electric cars are in the right place at the right time. They use their skills to organize and manage the flow of parts from suppliers to the manufacturing facility. These coordinators follow specific plans and schedules to ensure that the parts arrive on time and in the correct quantities.

Battery Pack Material Handler:

- Battery Pack Material Handlers manage the materials needed to build the batteries that power electric cars. They use their skills to organize and handle the different parts and components used in making the battery packs. These material handlers follow specific guidelines to ensure that the materials are stored, transported, and delivered correctly.

EV Assembly Line Support Worker:

- EV Assembly Line Support Workers help the assembly line run smoothly. They use their skills to assist the technicians and operators on the production line, making sure everything works well. These support workers help with tasks like moving materials, keeping the work area organized, and fetching tools or parts.

ICE-V Production Job Description

Quality Control Inspector – 22230 (NOC 2021) | 2261 (NOC 2016):

- Quality Control Inspectors in the manufacturing stage of ICE-V production check vehicles to make sure they are built correctly and work well. They carefully examine vehicles and their parts to make sure everything meets high quality standards. This role involves careful attention to detail and making sure each vehicle is in excellent condition before it goes out to customers.

Transferable Skills

- EV Quality Assurance Specialist: Inspection expertise, adherence to specifications, defect identification knowledge, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process improvement experience, and an understanding of quality assurance processes.

- Battery Pack Quality Control Inspector: Inspection expertise, defect identification knowledge, adherence to specifications, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process improvement experience, and an understanding of quality control processes.

- Charging Infrastructure Quality Inspector: Inspection expertise, defect identification knowledge, adherence to specifications, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process improvement experience, and an understanding of quality control processes.

Upskilling/Training

- EV Quality Assurance Specialist: Upskilling entails acquiring expertise in electric powertrain components, battery systems, charging infrastructure, and EV-specific quality control procedures, while training in areas such as battery performance testing, electrical system diagnostics, and integration of electric powertrain components.

- Battery Pack Quality Control Inspector: Upskilling requires developing proficiency in battery pack assembly processes, cell handling procedures, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, pack integration standards, and electric powertrain quality assessment.

- Charging Infrastructure Quality Inspector: Upskilling involves acquiring proficiency in EV charging infrastructure components, electrical assembly processes, smart charging systems, and high-voltage safety protocols, while training in areas such as charging station integration, communication interfaces, and quality assessment of charging infrastructure components.

Educational Requirements

- Quality Control Inspector (ICE-V): High school diploma or equivalent education with relevant technical training or certifications.

- EV Quality Assurance Specialist (EV): High school diploma or equivalent education with on-the-job training.

- Battery Pack Quality Control Inspector (EV): High school diploma or equivalent education with on-the-job training.

- Charging Infrastructure Quality Inspector (EV): High school diploma or equivalent education with on-the-job training.

EV Production Job Descriptions

EV Quality Assurance Specialist:

- EV Quality Assurance Specialists make sure that EVs are built to high standards of quality. They use their skills to inspect and check the vehicles for any issues or defects. These specialists follow specific guidelines and tests to ensure that EVs are safe, reliable, and meet quality standards.

Battery Pack Quality Control Inspector:

- Battery Pack Quality Control Inspectors ensure that the battery packs used in EVs are made to high standards of quality. They use their skills to carefully examine and test the battery packs for any issues or defects. These inspectors follow specific guidelines and tests to make sure the battery packs are safe, efficient, and meet quality standards.

Charging Infrastructure Quality Inspector:

- Charging Infrastructure Quality Inspectors ensure that the charging stations for EVs are made to high standards of quality. They use their skills to carefully examine and test the charging stations for any issues or defects. These inspectors follow specific guidelines and tests to make sure the charging stations are safe, efficient, and meet quality standards.

ICE-V Production Job Description

Logistics Coordinator – 13201 (NOC 2021) | 1523 (NOC 2016):

- Logistics Coordinators in the manufacturing stage of ICE-V production help organize the movement of materials and parts needed for manufacturing vehicles. They plan and arrange for materials to be delivered to factories at the right time. They work closely with suppliers, transportation companies, and manufacturers to ensure everything runs smoothly.

Transferable Skills

- EV Supply Chain Coordinator: Supply chain management, inventory coordination, vendor communication, transportation logistics, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process optimization experience, and an understanding of logistics processes.

- Battery Logistics Manager: Supply chain management, inventory coordination, vendor communication, transportation logistics, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process optimization experience, and an understanding of logistics processes.

- Charging Infrastructure Logistics Coordinator: Supply chain management, inventory coordination, vendor communication, transportation logistics, data analysis, familiarity with manufacturing regulations and standards, attention to detail, problem-solving skills, adaptability, communication abilities, teamwork, process optimization experience, and an understanding of logistics processes.

Upskilling/Training

- EV Supply Chain Coordinator: Upskilling requires developing expertise in electric vehicle components, battery systems, charging infrastructure, and sustainable sourcing practices, while training in areas such as EV-specific parts inventory management, battery supply chain logistics, and regulatory compliance for electric vehicle production.

- Battery Logistics Manager: Upskilling involves gaining proficiency in battery pack components, cell handling procedures, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, pack assembly processes, and electric powertrain integration.

- Charging Infrastructure Logistics Coordinator: Upskilling requires acquiring expertise in EV charging infrastructure components, electrical assembly processes, smart charging systems, and high-voltage safety protocols, while training in areas such as charging station deployment logistics, communication interfaces, and regulatory compliance for charging infrastructure.

Educational Requirements

- Logistics Coordinator (ICE-V): Diploma in logistics, supply chain management, business administration, or related field.

- EV Supply Chain Coordinator (EV): Diploma in logistics, supply chain management, business administration, or related field.

- Battery Logistics Manager (EV): Bachelor’s degree in logistics, supply chain management, business administration, or related field.

- Charging Infrastructure Logistics Coordinator (EV): Diploma in logistics, supply chain management, business administration, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Production Job Descriptions

EV Supply Chain Coordinator:

- EV Supply Chain Coordinators make sure all the necessary parts and materials for building EVs are available when needed. They use their skills to manage and organize the flow of supplies from different sources to the manufacturing facility. These coordinators follow specific plans and schedules to ensure that the parts arrive on time and in the right quantities.

Battery Logistics Manager:

- Battery Logistics Managers make sure all the materials needed to create the batteries for EVs are well-organized and available on time. They use their skills to plan and manage the movement of materials from different places to the manufacturing facility. These managers follow specific schedules and strategies to ensure that the materials arrive when needed and in the right amounts.

Charging Infrastructure Logistics Coordinator:

- Charging Infrastructure Logistics Coordinators make sure all the components and materials needed for creating charging stations are well-organized and delivered on time. They use their skills to plan and manage the movement of these items from various places to the manufacturing facility. These coordinators follow specific schedules and strategies to ensure that the components arrive when required and in the correct quantities.

ICE-V Production Job Description

Mechanical Assemblers and Inspectors – 94204 (NOC 2021) | 9526 (NOC 2016):

- Mechanical Assemblers and Inspectors in the manufacturing stage of ICE-V production put car parts together and check to make sure they are put together correctly. They use tools to assemble different pieces like engines, gears, and other parts of the vehicle. They also ensure everything fits properly and functions correctly after assembly.

Transferable Skills

- EV Component Assembler: Component assembly, quality control inspection, mechanical aptitude, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process efficiency, and an understanding of manufacturing processes.

- Battery Module Assembler and Inspector: Component assembly, quality control inspection, mechanical aptitude, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process efficiency, and an understanding of manufacturing processes.

- Charging Station Assembler and Tester: Component assembly, quality control inspection, mechanical aptitude, adherence to specifications, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process efficiency, and an understanding of manufacturing processes.

Upskilling/Training

- EV Component Assembler: Upskilling involves developing proficiency in electric vehicle component assembly processes, battery integration techniques, high-voltage safety protocols, and EV-specific quality control procedures, while training in areas such as electric powertrain modules, battery pack installation, and electric motor integration.

- Battery Module Assembler and Inspector: Upskilling requires acquiring expertise in battery module assembly processes, cell handling procedures, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, module integration standards, and electric powertrain quality assessment.

- Charging Station Assembler and Tester: Upskilling involves gaining proficiency in EV charging station components, electrical assembly processes, communication interfaces, and high-voltage safety protocols, while training in areas such as charging station integration, testing procedures, and regulatory compliance for charging infrastructure.

Educational Requirements

- Mechanical Assembler and Inspector (ICE-V): High school diploma or equivalent education and on-the-job training.

- EV Component Assembler (EV): High school diploma or equivalent education and on-the-job training.

- Battery Module Assembler and Inspector (EV): High school diploma or equivalent education and on-the-job training.

- Charging Station Assembler and Tester (EV): High school diploma or equivalent education and on-the-job training.

EV Production Job Descriptions

EV Component Assembler:

- EV Component Assemblers put together the different parts that make up EVs. They use their skills to assemble and connect various components, like motors, batteries, and other important parts. These assemblers follow specific instructions and guidelines to ensure that the components are put together accurately and securely.

Battery Module Assembler and Inspector:

- Battery Module Assemblers and Inspectors build and check the battery modules that power EVs. They use their skills to assemble the various parts of the battery modules, such as the battery cells, wiring, and connectors. These assemblers and inspectors follow specific instructions and guidelines to ensure that the modules are put together accurately and safely.

Charging Station Assembler and Tester:

- Charging Station Assemblers and Testers build and test the charging stations used to recharge EVs. They use their skills to assemble the different parts of the charging stations, following specific instructions and guidelines. These assemblers and testers work with precision to ensure that the stations are put together accurately and safely.

Maintenance

EV maintenance refers to the regular upkeep, servicing, and repairs required to keep EVs in optimal operating condition. It involves a range of activities aimed at ensuring the safety, performance, and longevity of EV components and systems. EV maintenance is typically performed by trained technicians or authorized service centres and includes preventive maintenance, inspections, software updates, and occasional repairs or component replacements.

The following transitions to EV careers in maintenance can be made by those with automotive knowledge and experience. Each of the below career pathways represents a traditional manufacturing or an ICE-V production job transitioning (➤) to multiple potential EV careers with transferable skillsets.

ICE-V Maintenance Job Description

Maintenance Technician – 72410 (NOC 2021) | 7321 (NOC 2016):

- ICE-V Maintenance Technicians ensure vehicles are running smoothly. They use their skills to check and fix problems with the vehicles’ engines and other important parts. These technicians perform regular inspections, change fluids, and replace worn-out components to keep the cars in good shape. They use tools and knowledge to troubleshoot and repair any issues they find.

Transferable Skills

- EV Maintenance Technician: Equipment troubleshooting, preventive maintenance expertise, mechanical and electrical repairs, diagnostic tool utilization, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process optimization experience, and an understanding of maintenance procedures.

- Battery System Maintenance Specialist: Equipment troubleshooting, preventive maintenance expertise, mechanical and electrical repairs, diagnostic tool utilization, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process optimization experience, and an understanding of maintenance procedures.

Upskilling/Training

- EV Maintenance Technician: Upskilling requires developing expertise in electric powertrain systems, battery diagnostics, charging infrastructure, and high-voltage safety protocols, while training in areas such as EV-specific maintenance procedures, battery maintenance, and electric motor troubleshooting.

- Battery System Maintenance Specialist: Upskilling involves acquiring proficiency in battery system diagnostics, thermal management strategies, cell balancing techniques, and high-voltage safety protocols, while training in areas such as battery chemistry, pack maintenance procedures, and electric powertrain integration.

Educational Requirements

- Maintenance Technician (ICE-V): High school diploma or equivalent education and completion of apprenticeship.

- EV Maintenance Technician (EV): Diploma in automotive technology, electrical engineering technology, or related field.

- Battery System Maintenance Specialist (EV): Diploma in electrical engineering technology, electronics, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- St. Clair College – Electric Drive Vehicle Technician

- St. Clair College – Electrical Engineering Technician

EV Maintenance Job Descriptions

EV Maintenance Technician:

- EV Maintenance Technicians keep EVs in good working condition. They use their skills to inspect, repair, and maintain the vehicles after they’ve been made. These technicians follow specific guidelines and use their expertise to fix any issues, replace parts, and ensure that the EVs are running smoothly.

Battery System Maintenance Specialist:

- Battery System Maintenance Specialists keep the battery packs of EVs in good condition. They use their skills to inspect, service, and repair the battery systems to ensure they work properly. These specialists follow specific guidelines and use their expertise to identify and fix any issues with the battery packs.

ICE-V Maintenance Job Description

Automotive Parts Specialist – 14401 (NOC 2021) | 1522 (NOC 2016):

- Automotive Parts Specialists have an extensive knowledge of different parts that make up an ICE-V’s engine and other important components. They help customers find the right parts they need to fix their vehicles. These specialists understand how ICE-V engines work and can recommend the best parts for repairs.

Transferable Skills

- EV Parts Specialist: Parts identification, inventory management, supplier communication, quality control awareness, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process optimization experience, and an understanding of parts logistics.

- Battery System Parts Coordinator: Parts identification, inventory management, supplier communication, quality control awareness, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process optimization experience, and an understanding of parts logistics.

Upskilling/Training

- EV Parts Specialist: Upskilling requires developing expertise in electric vehicle components, battery systems, charging infrastructure, and high-voltage safety protocols, while training in areas such as EV-specific parts identification, battery replacement procedures, and electric powertrain integration.

- Battery System Parts Coordinator: Upskilling involves gaining proficiency in battery system components, cell technologies, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, pack integration standards, and electric powertrain parts coordination.

Educational Requirements

- Automotive Parts Specialist (ICE-V): Diploma in automotive technology, engineering, business administration, or related field.

- EV Parts Specialist (EV): Diploma in automotive technology, engineering, business administration, or related field.

- Battery System Parts Coordinator (EV): Diploma in supply chain management, logistics, business administration, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Maintenance Job Descriptions

EV Parts Specialist:

- EV Parts Specialists manage and replace the different parts needed for EVs. They use their skills to identify, source, and replace parts that might need fixing due to wear and tear. These specialists follow specific guidelines and use their expertise to ensure that the correct and high-quality parts are used.

Battery System Parts Coordinator:

- Battery System Parts Coordinators manage and organize the various parts needed for the battery systems in EVs. They use their skills to make sure the right parts are available when needed for repairs or replacements. These coordinators follow specific plans and schedules to ensure that the correct parts arrive on time and in the right quantities.

ICE-V Maintenance Job Description

Storekeepers and Partspersons – 14401 (NOC 2021) | 1522 (NOC 2016):

- Storekeepers and Partspersons take care of the parts and tools needed to fix cars. Their job is to organize the inventory, keep track of what is in stock, and help customers find the right parts for their vehicles. They may also assist with orders and deliveries.

Transferable Skills

- EV Parts Inventory Coordinator: Inventory management, parts handling expertise, data entry, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, attention to detail, teamwork, communication abilities, process optimization experience, and an understanding of parts logistics

- Battery System Parts Specialist: Inventory management, parts handling expertise, data entry, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, attention to detail, teamwork, communication abilities, process optimization experience, and an understanding of parts logistics.

- Charging Equipment Parts Manager: Inventory management, parts handling expertise, data entry, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, attention to detail, teamwork, communication abilities, process optimization experience, and an understanding of parts logistics.

Upskilling/Training

- EV Parts Inventory Coordinator: Upskilling requires developing expertise in electric vehicle components, battery systems, charging infrastructure, and sustainable sourcing practices, while training in areas such as EV-specific parts inventory management, battery pack components, and electric powertrain integration.

- Battery System Parts Specialist: Upskilling involves acquiring proficiency in battery system components, cell technologies, thermal management considerations, and high-voltage safety protocols, while training in areas such as battery chemistry, pack integration standards, and electric powertrain parts expertise.

- Charging Equipment Parts Manager: Upskilling requires developing expertise in EV charging equipment components, electrical systems, communication interfaces, and high-voltage safety protocols, while training in areas such as charging station parts inventory management, fast-charging technologies, and charging infrastructure compatibility.

Educational Requirements

- Storekeeper and Partsperson (ICE-V): High school diploma or equivalent education and on-the-job training.

- EV Parts Inventory Coordinator (EV): Diploma in inventory management, supply chain management, business administration, or related field.

- Battery System Parts Specialist (EV): Diploma in automotive technology, engineering technology, business administration, or related field.

- Charging Equipment Parts Manager (EV): Diploma in business administration, supply chain management, electrical engineering technology, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Maintenance Job Descriptions

EV Parts Inventory Coordinator:

- EV Parts Inventory Coordinators manage and organize the supply of different parts needed to keep EVs running smoothly. They use their skills to keep track of the inventory of parts, making sure they have enough in stock for repairs and replacements. These coordinators follow specific plans and use their expertise to ensure that the right parts are available when needed.

Battery System Parts Specialist:

- Battery System Parts Specialists manage and handle the various parts needed for the battery systems in EVs. They use their skills to identify, source, and replace parts that might need repairing or replacing over time. These specialists follow specific guidelines and use their expertise to ensure that the correct and high-quality parts are used for maintenance.

Charging Equipment Parts Manager:

- Charging Equipment Parts Managers manage and oversee the supply of different parts needed for maintaining the charging stations used by EVs. They use their skills to ensure that the right parts are available when needed for repairs and replacements. These managers follow specific plans and schedules to make sure the correct parts are in stock.

ICE-V Maintenance Job Description

Motor Vehicle Body Repairers – 72411 (NOC 2021) | 7322 (NOC 2016):

- Motor Vehicle Body Repairers fix the outside parts of cars that might be damaged. They work on things like dents, scratches, and other problems on the vehicle’s body. They use tools to complete this work and may also replace damaged parts and paint the vehicle if necessary.

Transferable Skills

- EV Body Repair Technician: Body repair expertise, welding proficiency, panel alignment knowledge, refinishing techniques, use of repair tools, attention to detail, familiarity with manufacturing regulations and standards, adaptability, problem-solving skills, teamwork, communication abilities, process efficiency, and an understanding of repair procedures.

Upskilling/Training

- EV Body Repair Technician: Upskilling involves gaining proficiency in electric vehicle body materials, structural repair techniques, battery safety protocols, and high-voltage system handling, while training in areas such as EV-specific body repair procedures, battery enclosure repair, and electric powertrain integration.

Educational Requirements

- Motor Vehicle Body Repairer (ICE-V): High school diploma and completion of apprenticeship or vocational training.

- EV Body Repair Technician (EV): High school diploma and completion of apprenticeship or vocational training.

EV Maintenance Job Description

EV Body Repair Technician:

- EV Body Repair Technicians fix and restore the exterior of EVs. They use their skills to repair any damages, dents, or scratches that the vehicle might have sustained. These technicians follow specific procedures to ensure that the repairs are done accurately and safely.

Scientific Research

EV scientific research refers to the systematic investigation and study conducted by scientists, researchers, and experts in various fields to advance the knowledge and understanding of EVs. It involves conducting experiments, analyzing data, and publishing findings to contribute to the development, improvement, and adoption of EV technologies. EV scientific research encompasses a wide range of disciplines, including engineering, materials science, chemistry, physics, energy storage, electronics, and environmental sciences.

EV scientific research plays a crucial role in advancing the state of EV technology, addressing challenges, and unlocking new possibilities for electric transportation. It fosters innovation, collaboration, and knowledge sharing among researchers, industry experts, and policymakers to drive the sustainable development and widespread adoption of EVs. Scientific research in the EV sector involves the collaboration of public and private sectors to research, develop, demonstrate, and deploy technologies that enhance the performance of EVs. Examples of this may be to improve and enhance activities such as battery performance, recharging technology, and material sourcing and usage.

The following transitions to EV careers in scientific research can be made by those with automotive knowledge and experience. Each of the below career pathways represents a traditional manufacturing or an ICE-V production job transitioning (➤) to multiple potential EV careers with transferable skillsets.

ICE-V Production Job Description

Mechanical Engineer – 21301 (NOC 2021) | 2132 (NOC 2016):

- Mechanical Engineers in the scientific research stage of ICE-V production investigate and improve the performance of traditional car engines. They use engineering skills to study how engines work, find ways to make them more efficient, and develop new ideas to enhance their power and fuel economy.

Transferable Skills

- EV Battery Engineer: Fundamental engineering principles, materials science, thermal management, fluid dynamics, computer-aided design (CAD), numerical analysis and simulation, electrical knowledge, data analysis, project management, problem-solving, team collaboration, regulatory knowledge, communication skills, innovation and creativity, safety and reliability, and continuous learning.

- Electric Powertrain Engineer: Fundamental engineering principles, systems thinking, electric fundamentals, controls and automation, modeling and simulation, energy management, mechanical design, CAD, data analysis, safety and reliability, team collaboration, problem-solving, project management, communication skills, adaptability, regulatory knowledge, innovation, and creativity.

Upskilling/Training

- EV Battery Engineer: Battery technology, power electronics, materials science, and electric drive systems, while training in areas such as battery chemistry, thermal management, and EV charging infrastructure.

- Electric Powertrain Engineer: Electric powertrain design, electric motor technologies, energy management systems, and high-voltage electronics, while training in areas such as battery integration, motor control algorithms, and power electronics.

Local upskilling opportunities can be found here:

Educational Requirements

- Mechanical Engineer (ICE-V): Bachelor’s degree in mechanical engineering.

- EV Battery Engineer (EV): Bachelor’s degree in electrical engineering, chemical engineering, or related field.

- Electric Powertrain Engineer (EV): Bachelor’s degree in electrical engineering, automotive engineering, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- St. Clair College – Mechanical Engineering Technology – Automotive Product Design

- University of Windsor – Electrical Engineering

- University of Windsor – Mechanical Engineering

EV Production Job Description

EV Battery Engineer:

- EV Battery Engineers in the scientific research stage of EV production focus on improving the batteries that power EVs. They study how the batteries work, finding ways to make them better, and coming up with new ideas to enhance their efficiency, range, and reliability.

Electric Powertrain Engineer:

- Electric Powertrain Engineers in the scientific research stage of EV production enhance the performance and efficiency of the technology that drives EVs. They investigate how electric powertrains work, discovering ways to make them better, and creating new ideas to improve their overall effectiveness.

ICE-V Production Job Description:

Industrial Engineer (ICE-V Production) – 21321 (NOC 2021) | 2141 (NOC 2016):

- Industrial Engineers in the scientific research stage of ICE-V production focus on optimizing the manufacturing processes that build vehicles. They study how vehicles are made, finding ways to make production better, and help to enhance efficiency, quality, and safety.

Transferable Skills

- Battery Technology Research Engineer: Process optimization, data analysis, statistical analysis, project management, collaboration and communication abilities, systems thinking, risk management, root cause analysis, lean manufacturing principles, quality control expertise, adaptability, environmental awareness, materials selection knowledge, safety protocol adherence, testing and validation experience, economic analysis aptitude, regulatory understanding, and continuous improvement.

- Electric Powertrain Engineer: Process optimization, data analysis, statistical analysis, project management, collaboration and communication abilities, systems thinking, risk management, root cause analysis, lean manufacturing principles, quality control expertise, adaptability, environmental awareness, economic analysis aptitude, policy analysis understanding, partner engagement, problem-solving skills, mechanical knowledge, familiarity with regulations and standards, and continuous improvement.

- Charging Infrastructure Research Analyst: Process optimization, data analysis, statistical analysis, project management, collaboration and communication abilities, systems thinking, risk management, root cause analysis, lean manufacturing principles, quality control expertise, adaptability, environmental awareness, economic analysis aptitude, policy analysis understanding, partner engagement, problem-solving skills, regulatory knowledge, and continuous improvement.

Upskilling/Training

- Battery Technology Research Engineer: Battery chemistry, materials science, energy storage systems, and advanced characterization techniques, while training in areas such as electrochemical engineering, battery safety, and sustainable manufacturing processes.

- Electric Powertrain Engineer: Electric powertrain design, motor technologies, energy management systems, and power electronics, while training in areas such as electric drive control, battery integration, and sustainable mobility concepts.

- Charging Infrastructure Research Analyst: EV charging technologies, grid integration, renewable energy systems, and smart charging management, while training in areas such as electric vehicle communication protocols, energy storage solutions, and urban mobility planning.

Local upskilling opportunities can be found here:

Educational Requirements

- Industrial Engineer (ICE-V): Bachelor’s degree in industrial engineering.

- Battery Technology Research Engineer (EV): Bachelor’s degree in chemical engineering, materials science, electrical engineering, or related field.

- Electric Powertrain Engineer (EV): Bachelor’s degree in electrical engineering, automotive, engineering, or related field.

- Charging Infrastructure Research Analyst (EV): Bachelor’s degree in electrical engineering, renewable energy, sustainable transportation, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- University of Windsor – Electrical Engineering

- University of Windsor – Industrial Engineering

- University of Windsor – Mechanical Engineering

EV Production Job Descriptions:

Battery Technology Research Engineer:

- Battery Technology Research Engineers focus on making better batteries for EVs. They use their knowledge to study and improve the technology that stores energy in the batteries. These engineers work to develop batteries that can go longer distances on a single charge and charge up more quickly.

Electric Powertrain Engineer (EV Production):

- Electric Powertrain Engineers work on making EVs run smoothly and efficiently. They focus on the powertrain, which includes the parts that make the vehicle move using electricity. These engineers study and design systems that control how electric power is used to propel the vehicle.

Charging Infrastructure Research Analyst (EV Production):

- Charging Infrastructure Research Analysts focus on creating better ways to charge EVs. They use their skills to study and improve the places where EVs get charged. These analysts work on finding solutions to make charging stations faster, more convenient, and widely available.

ICE-V Production Job Description

Electrical Engineer – 21310 (NOC 2021) | 2133 (NOC 2016):

- Electrical Engineers in the scientific research stage of ICE-V production focus on enhancing the electrical systems in vehicles. They study how electrical components work and work to improve vehicle performance, safety, and technology.

Transferable Skills

- Electric Powertrain Engineer: Circuit design and analysis, control systems expertise, digital signal processing knowledge, power electronics proficiency, modeling and simulation abilities, energy storage understanding, programming skills, system integration aptitude, testing and validation experience, electrical safety adherence, problem-solving skills, adaptability, and familiarity with regulations and standards.

- Battery Management Systems Engineer: Circuit design, control systems expertise, digital signal processing knowledge, embedded systems proficiency, power electronics understanding, programming skills, data analysis aptitude, modeling and simulation experience, energy storage familiarity, electrical safety adherence, testing and validation capabilities, problem-solving skills, adaptability, and an awareness of regulations and standards.

- Charging Technology Researcher: Circuit design, control systems expertise, power electronics knowledge, digital signal processing proficiency, data analysis abilities, modeling and simulation experience, programming skills, project management aptitude, collaboration and communication abilities, adaptability, testing and validation proficiency, problem-solving skills, awareness of regulations and standards, environmental awareness, and an understanding of energy storage systems.

Upskilling/Training

- Electric Powertrain Engineer: Electric powertrain architecture, motor control strategies, battery integration, and high-voltage systems, while training in areas such as regenerative braking, energy management algorithms, and electric drive optimization.

- Battery Management Systems Engineer: Electric powertrain design, motor control algorithms, energy management systems, and advanced power electronics, while training in areas such as battery integration, regenerative braking, and electric drive optimization.

- Charging Technology Researcher: EV charging standards, fast-charging technologies, grid integration, and smart charging systems, while training in areas such as vehicle-to-grid communication, wireless charging, and energy storage solutions.

Local upskilling opportunities can be found here:

Educational Requirements

- Electrical Engineer (ICE-V): Bachelor’s degree in electrical engineering.

- Electric Powertrain Engineer (EV): Bachelor’s degree in electrical engineering, automotive, engineering, or related field.

- Battery Management Systems Engineer (EV): Bachelor’s degree in electrical engineering, control systems, or related field.

- Charging Technology Researcher (EV): Bachelor’s degree in electrical engineering, renewable energy, power electronics, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

EV Production Job Descriptions

Electric Powertrain Engineer (EV Production):

- Electric Powertrain Engineers specialize in making EVs work well. They focus on the powertrain, which is like the heart of the EV. These engineers use their knowledge to study and design the parts that help the car move using electricity.

Battery Management Systems Engineer (EV Production):

- Battery Management Systems Engineers focus on making batteries for EVs work well. They specialize in designing systems that control and monitor the batteries’ performance. These engineers use their knowledge to develop technology that ensures the batteries stay safe, last longer, and provide consistent power.

Charging Technology Researcher (EV Production):

- Charging Technology Researchers focus on making charging EVs better. They use their skills to study and develop new ways to charge EVs. These researchers work on finding technologies that can make charging faster, more efficient, and widely available.

ICE-V Production Job Description

Information Systems Analyst – 21222 (NOC 2021) | 2171 (NOC 2016):

- Information Systems Analysts involved in the scientific research stage of ICE-V production work with computers and data to support the development of better cars. They use their skills to gather, organize, and analyze information related to vehicle design and performance. These analysts help researchers understand how different parts of the car work together and how to make improvements.

Transferable Skills

- EV Systems Analyst: Data analysis, system architecture understanding, software development knowledge, database management expertise, cybersecurity awareness, project management skills, collaboration and communication abilities, adaptability, technical documentation proficiency, quality assurance experience, problem-solving skills, awareness of regulations and standards, and an aptitude for understanding vehicle systems.

- Battery Technology Analyst: Data analysis, system architecture understanding, software development knowledge, database management expertise, cybersecurity awareness, project management skills, collaboration and communication abilities, adaptability, technical documentation proficiency, quality assurance experience, problem-solving skills, awareness of regulations and standards, and an aptitude for understanding energy storage systems.

- Smart Charging Infrastructure Analyst: Data analysis, system architecture understanding, software development knowledge, cybersecurity awareness, project management skills, collaboration and communication abilities, adaptability, technical documentation proficiency, quality assurance experience, problem-solving skills, awareness of regulations and standards, and an aptitude for understanding smart charging technologies.

Upskilling/Training

- EV Systems Analyst: Electric vehicle architecture, vehicle communication protocols, battery management systems, and telematics, while training in areas such as electric powertrain integration, vehicle data analysis, and software for EV diagnostics

- Battery Technology Analyst: Battery chemistries, materials science, energy storage systems, and data analysis techniques, while training in areas such as battery diagnostics, degradation modeling, and performance optimization.

- Smart Charging Infrastructure Analyst: Smart charging technologies, energy management systems, grid integration, and Internet of Things (IoT) solutions, while training in areas such as vehicle-to-grid communication, demand response strategies, and real-time data analytics.

Educational Requirements

- Information Systems Analyst (ICE-V): Bachelor’s degree in information systems, computer science, or a related field.

- EV Systems Analyst (EV): Bachelor’s degree in electrical engineering, automotive engineering, or related field.

- Battery Technology Analyst (EV): Bachelor’s degree in materials science, chemistry, chemical engineering, electrical engineering, or related field.

- Smart Charging Infrastructure Analyst (EV): Bachelor’s degree in electrical engineering, computer science, or related field.

Below is a list of local educational opportunities for one or more of the careers listed above:

- University of Windsor – Computer Science

- University of Windsor – Chemistry

- University of Windsor – Electrical Engineering

- University of Windsor – Mechanical Engineering

EV Production Job Descriptions:

Electric Vehicle Systems Analyst:

- Electric Vehicle Systems Analysts study and understand how EVs work. They use their skills to analyze the different systems that make an EV run, like the power, control, and communication systems. These analysts work on finding ways to improve how these systems work together to make EVs efficient and reliable.

Battery Technology Analyst:

- Battery Technology Analysts study and improve the batteries used in EVs. They use their skills to analyze and understand how these batteries work. These analysts work on finding ways to make batteries store more energy, charge faster, and last longer.

Smart Charging Infrastructure Analyst:

- Smart Charging Infrastructure Analysts focus on creating advanced ways to charge EVs. They use their skills to study and develop smart technologies for charging stations. These analysts work on finding solutions to make charging more efficient, flexible, and connected.

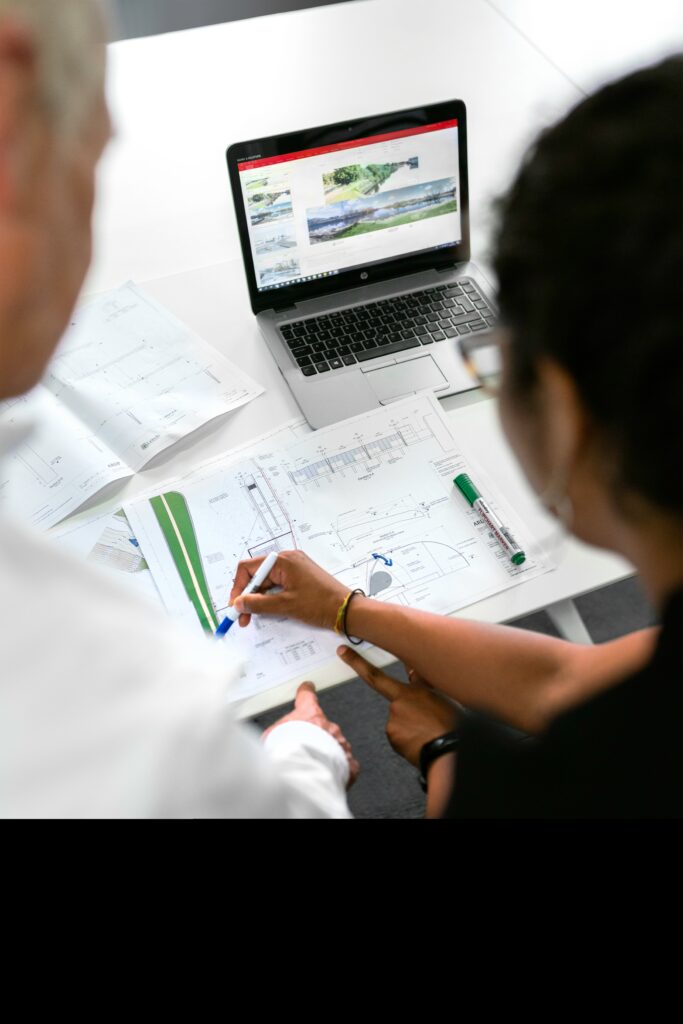

Design and Development

EV design and development refers to the process of creating and refining EVs. EV design involves various aspects, including the engineering and integration of electrical systems, battery technology, power electronics, drivetrain components, and overall vehicle architecture. It encompasses both the exterior and interior design elements of the vehicle, ensuring functionality, efficiency, safety, and aesthetics. EV design and development aims to create efficient, sustainable, and reliable EVs that are an alternative to traditional fossil-fuel powered transportation. It involves a multidisciplinary approach, bringing together engineering, design, materials science, and advanced technologies to shape the future of mobility.

The following transitions to EV careers in design and development can be made by those with automotive knowledge and experience. Each of the below career pathways represents a traditional manufacturing or an ICE-V production job transitioning (➤) to multiple potential EV careers with transferable skillsets.

ICE-V Production Job Description

Electrical Technicians – 22310 (NOC 2021) | 2241 (NOC 2016):

- Electrical Technicians in the design and development stage of ICE-V production focus on creating and testing electrical systems that power vehicles. They help design and build electrical components, ensuring they work correctly, and contribute to making vehicles safer, more efficient, and advanced.

Transferable Skills

- EV Powertrain Technician: Electrical systems troubleshooting, wiring and harnessing experience, component installation proficiency, electrical safety knowledge, diagnostic tool usage, vehicle testing familiarity, quality assurance awareness, collaboration and communication abilities, adaptability, mechanical aptitude, problem-solving skills, and an awareness of regulations and standards.

- Charging Infrastructure Specialist: Electrical systems installation and troubleshooting, wiring expertise, component integration knowledge, electrical safety awareness, diagnostic tool utilization, system testing familiarity, quality assurance experience, collaboration and communication abilities, adaptability, problem-solving skills, and an awareness of regulations and standards.

Upskilling/Training

- EV Powertrain Technician: Electric powertrain components, high-voltage systems, battery maintenance, and electric motor diagnostics, while training in areas such as EV safety protocols, energy storage technologies, and charging infrastructure.

- Charging Infrastructure Specialist: EV charging technologies, electrical infrastructure design, energy management systems, and fast-charging solutions, while training in areas such as electric vehicle communication protocols, grid integration, and sustainable charging infrastructure planning.

Local training and upskilling opportunities can be found here:

Educational Requirements

- Electrical Technician (ICE-V): Diploma in electrical engineering technology.

- EV Powertrain Technician (EV): Diploma in automotive technology or electrical engineering technology.

- Charging Infrastructure Specialist (EV): Bachelor’s degree in electrical engineering, renewable energy, or related field.