Workforce Profiles look at the people behind Workforce WindsorEssex’s 76 In-Demand Jobs. Each week, we talk to a different professional for an inside look into their work.

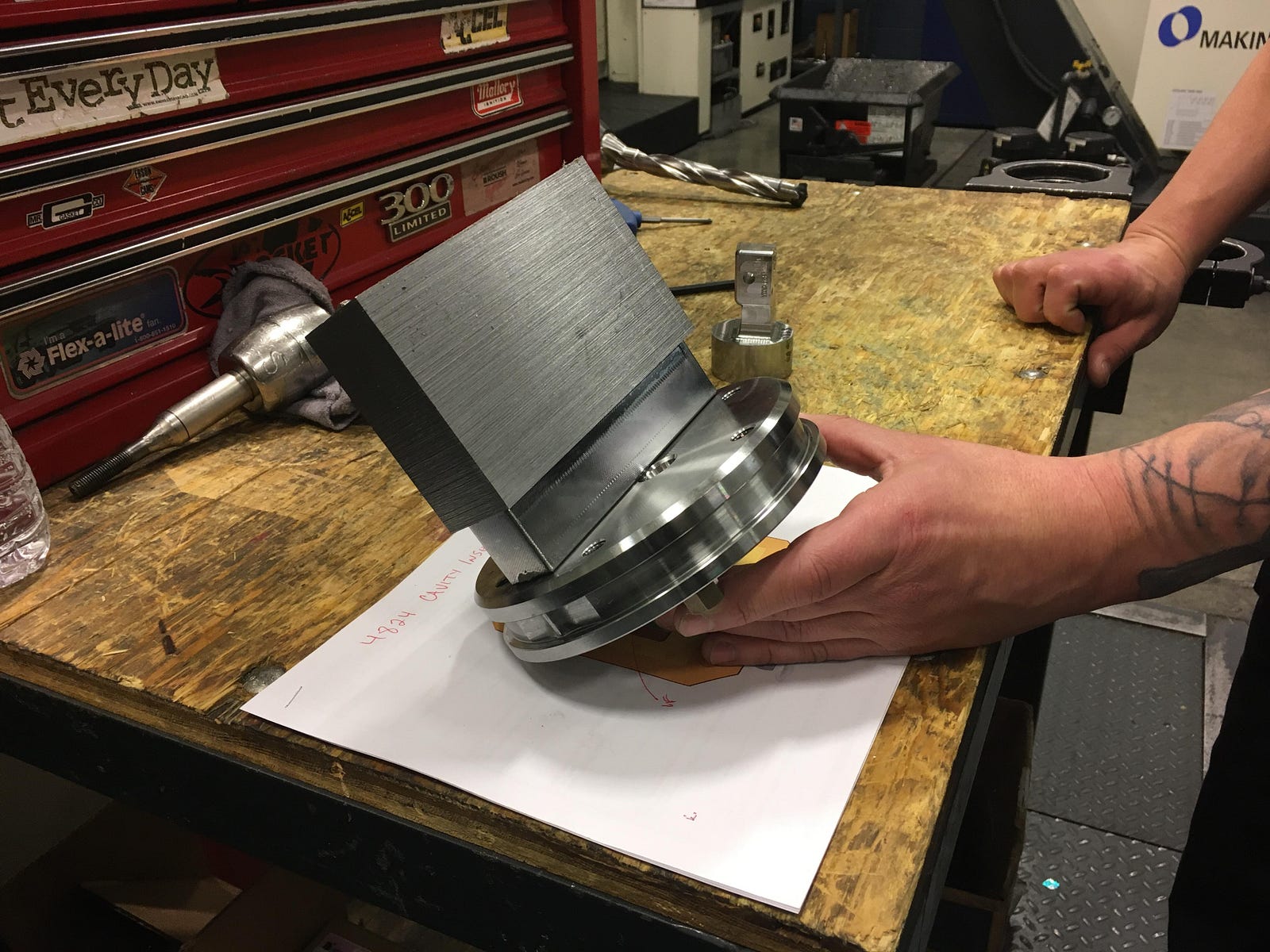

Looking around at the break room at Cavalier Tool; Jeremy, a CNC Machinist points out how everything plastic once came from a mold: backs of chairs, the kettle, a phone case.

Cavalier has been in business for over forty years and they create molds for automotive, commercial, recreational, heavy truck and agricultural industries. When Jeremy sees a product that once came from the molds at Cavalier Tool; “it makes me proud.”

Machinists set up, operate, and maintain a variety of machine tools including computer numerically controlled (CNC) tools to perform precision, non-repetitive machining operations.

Machinists and Machining and Tooling Inspectors are one of the most sought-after professions in Windsor-Essex, easily making our list of 76 In-Demand Jobs. Read the Career Profile here.

We sat down with Jeremy to ask him about his work and how he got started:

What’s an average day like?

Mornings is really busy with prep, especially with the machine I run. Once you’re set up, it’s a nice flow all day. You’re not super busy, but busy enough to make time go by.

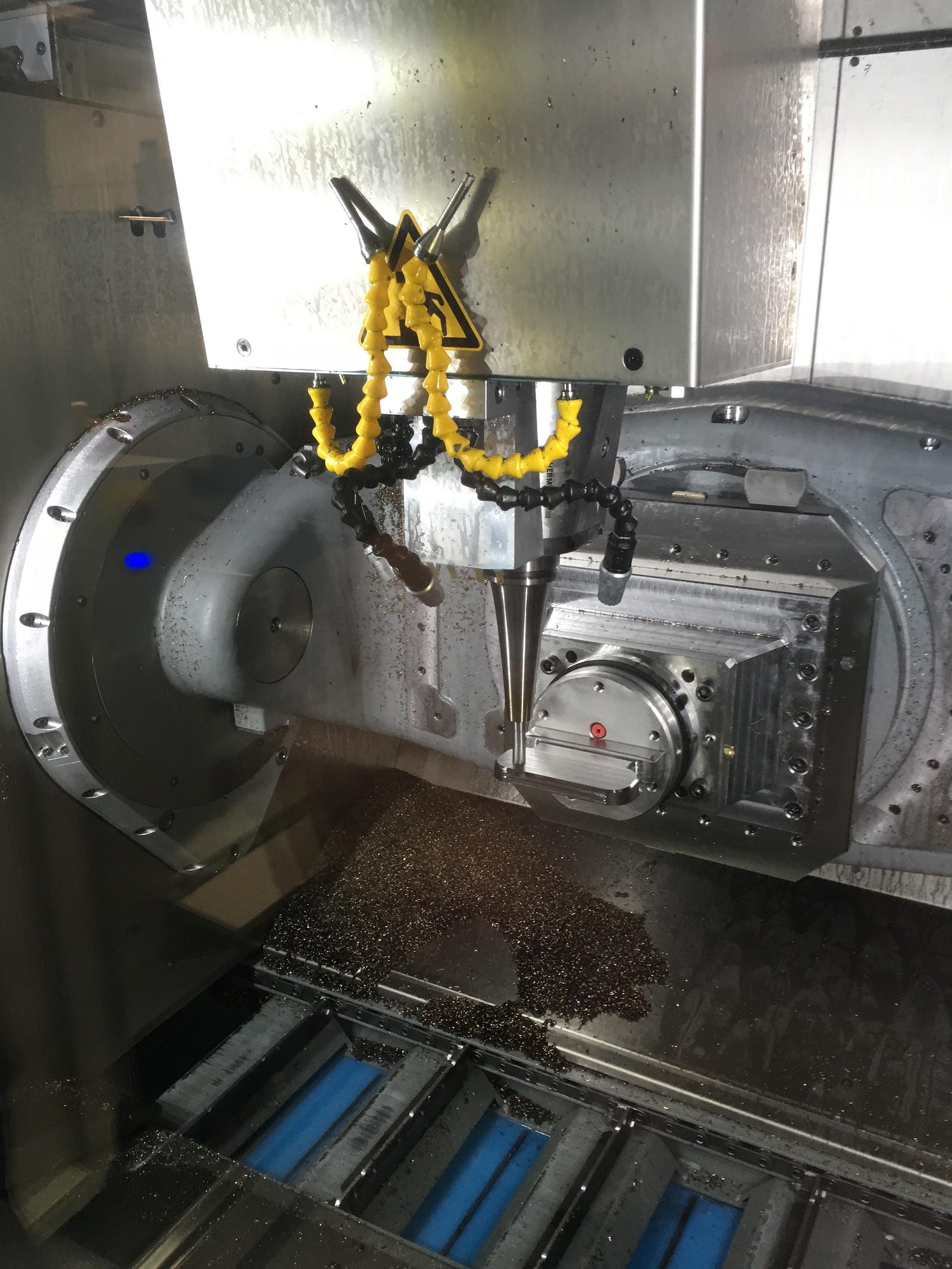

The machine I run is very precise. It’s a finishing machine. Everything has to be in 1000ths. It’s not just with quarter inches. I love watching the machine cut metal.

How long have you been in this job?

I’ve been here for about 5 years. Before this, I was in construction. I was renovating McDonald’s restaurants all over Ontario and I was never home. This was a good jump.

A friend was coming here to run new machines and there was an opening on one of their older machines. They gave me a chance and it happened to work out really well for me.

I went from one of the worst machines in the shop to one of the best — a million-and-a-half-dollar machine. You can advance really quickly.

What advice would you give to someone starting out?

Keep your nose clean and listen to the older guys. A lot of the guys with grey hair are really smart. You don’t have to put your two cents in all the time, you can listen to them.

Is safety an issue at the shop?

No, it’s very safe. Most of the machines are enclosed and you can’t get in there while it’s running. It’s not like in the 80’s and you could watch chips fly at you. It was a lot more dangerous back then.

How do you get trained to use new equipment?

They usually pair you up with one of the senior guys. I take tons of notes and write everything down, so you don’t keep bothering the guy. I take pictures with my phone or draw the controller and label them. There are manuals on the floor too.

If you get a good guy training you, most of them are super patient and want you to learn. They will never set you up to fail.

How could someone in high school get started into this field?

I would talk to a guidance councilor or shop teacher. See where they can go from there. Even start asking friends and relatives, handing out resumes if they’re really interested.

Cavalier is partners with Herman Secondary and we have a lot of co-op students. Co-op is really good if you want information and aren’t sure where you want to go.

Do you see yourself in this long-term?

The trades give back. We have an RSP plan where the employer matches the benefits. We get boot allowance, tool allowance, and as many hours as we want.

You aren’t picking up 100 LBS pieces of steel. One guy we had here was 72 when he retired.