Workforce Profiles look at the people behind Workforce WindsorEssex’s 120+ In-Demand Jobs. Each week, we talk to a different professional for an inside look into their work.

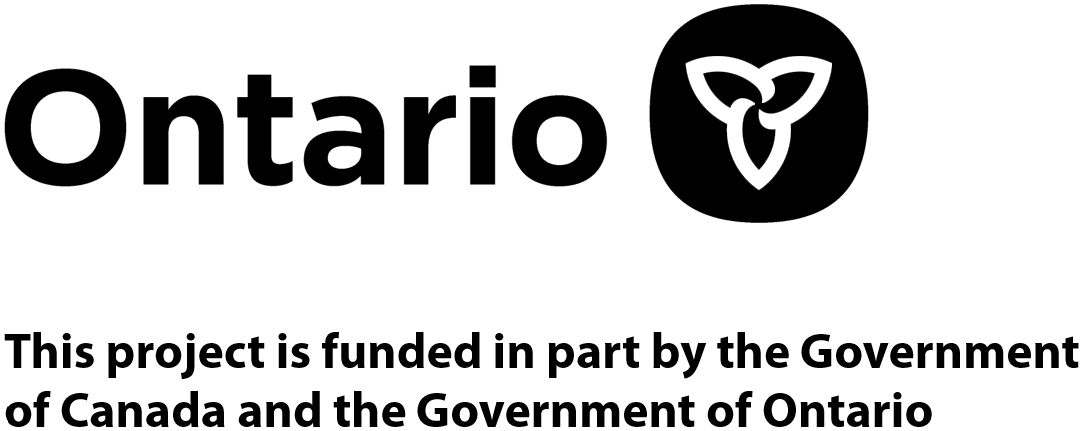

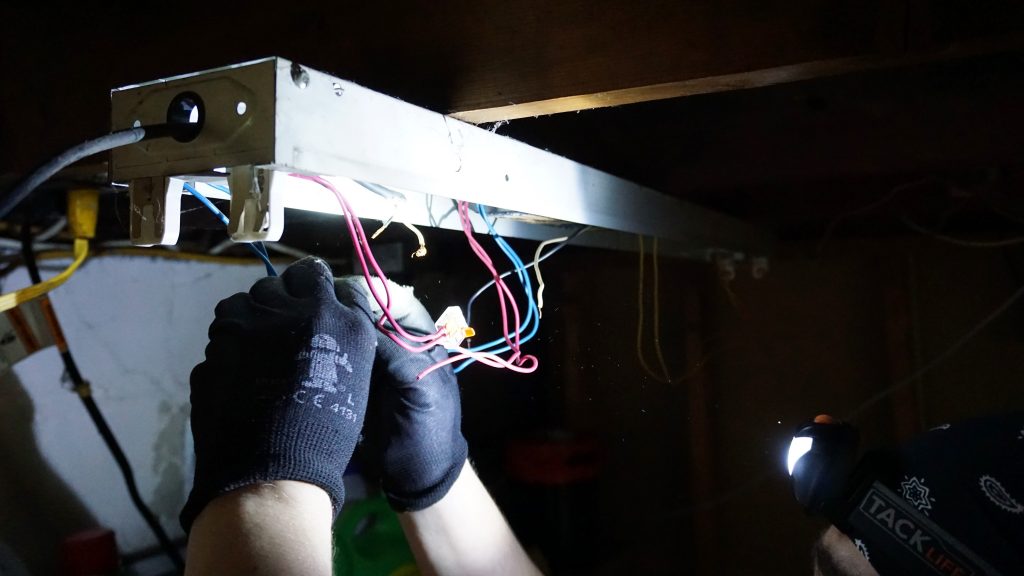

Adam Kaschak- is a 5th year Commercial/Residential Electrical Apprentice working for Powerserve/Neighbourhood Electric in Windsor. We got the opportunity to ask him about his career journey as he fixed a light fixture in a residential location.

What got you into this career? How long have you been in the field?

Right from graduating high-school I went right into the workforce as a general labourer on a construction site. I had a chance to work with all the trades and while working alongside the electricians and I decided that’s what I wanted to be doing.

So I went to the pre-apprenticeship program at St. Clair College- the electrical techniques course. Was an 8 month course and then I had to find a job placement to earn my apprenticeship hours. That took me a little while- unlike the guys today who can find one no problem.

To become a licenced electrician, first you have to be signed on for an apprenticeship. Then you go through 3 terms of school and have to work 9000 hours in the field, and then write your test. Because you are working while you learn, those 9000 are paid, and you only need to go on unemployment while in school for the 3 months at a time.

I have been through 2 terms of school, and have over 12000 hours. I need the last, third, section of schooling and I’m going in March to do that.

Once I’m done school I can write my test right away- so within the year I’ll be certified. I’ve been waiting on school for a while. School chooses when you go, I didn’t get to choose- or I would have been done a while ago. Every year or two the government sends out the letters. I will say that without the Ontario College of Trades I think that things are going to be easier for anyone wanting to get into this field.

This is because 7 years ago when I started, I struggled to get a job because I couldn’t get into a company without a certain number of journey people (licenced electricians) there. The ratio was 3 journeymen to one apprentice and that really held a lot of companies back from taking on more apprentices. The good news now for anyone going into the field- if you go through the pre-apprenticeship program at the college first, it counts for your first year of school. Speeds up the process a bit, while also ensuring you get the schooling and training you need.

What would you recommend for someone starting out in the field?

There are two ways you could do it. One would be like I did- take the Electrical Tech Course, find a place to take you on for your apprenticeship and then continue school and working.

The second option though, is what my company does, they hire someone on with no experience as a general labour, and if its a good fit they hire them on to do their apprenticeship. Then they go to school from there.

I personally would recommend the Techniques Class at St. Clair though. It’s a one year program Sept-April that not only serves as your first year of school- it teaches you the fundamentals that you should really have before you start on the hands-on job.

How did your training prepare you for the job?

Both school and the hands-on training really prepared me. School was good because it teaches electrical theory, and things that you wouldn’t normally run into on the job. It’s great because if you were to run into a problem later on, you probably know how to fix it already because of the Electrical Theory schooling. Everyone always says “There’s always more than one way to skin a cat.” they mean that there might be 15 different ways to do something and you need to use your best judgement to figure out which way is best for the situation. It might be the easiest way, or the most cost effective, or the easiest based on materials available from the wholesaler. If you need special materials it may take time, but if you know theory, you can probably try out something else and it’ll work out.

School also prepared me because it drilled the Code Book into us. Everything needs to get inspected by Electrical Safety Authority, and it costs the company money when there is a code defect. You need to know the codes to do the job right the first time and not cost the company money or time.

The electrical trade is extremely strict about codes and safety procedure because of the high risk factor.

Speaking of the high risk factor, is it challenging to ensure your safety on the job?

If you do your due diligence in ensuring the power is off, and you make sure the testing is done correctly, you have nothing to worry about. Sometimes I do have to work with a live wire, but I’m trained for that. There is very little risk when you’re careful about it.

Another good thing about my trade is that I’m paid more than the average trade because of the high risk factor. But as long as you follow procedures, and know what you’re doing, it’s perfectly safe.

What does the average day look like for you?

My job is different every single day. One day I could be in someone’s house just changing out a plug, another day I could be at a commercial site running new feed in ceilings. Sometimes, it’s a ground-up project on an empty lot.

The biggest project I’ve worked on is probably our 650 Division project. That project was from the ground up we started with an empty field. All of the electrical pipes were installed underground for the buildings, for the parking lot lights and for the main feed. Now it’s a shopping center with a Dollarama and Ashley Home store. I get to go to those places now and say “The lights are on in here because I helped with that.” That’s a great feeling.

When working on a project from the ground-up I get there with the people excavating and I have to run the pipes. When the base building starts going up, with the bricklayers, I have to work along with them to put all of the pipes and boxes inside the brick walls. Then there’s the ceilings, and I work with the carpenters.

Can it be a challenge working with other crews?

So many different crews working together can be a challenge. Sometimes there’s a bit of an ego war between the trades, which is understandable when everyone is trying to get their job done, on their own crew’s schedule. Our job depends on what stage the builders are at in the build. But their job doesn’t depend on us. We have to get in there with the brick, but before the drywall is up, or else we’re having to break into walls, and that would upset some people. So I need to focus on what I’m doing, and what step the build as a whole is at. Whereas the other trades just need to come and make sure their job is done.

The most challenging part of the job for me though is reading the prints. I have to look at a bunch of pieces of paper, and see where things need to go, and at what height, and how much, and then I have to talk it out with other crews.

Do you see yourself doing this long term?

Absolutely, I couldn’t imagine myself doing anything else. I’ve always wanted to work with my hands. I could never sit at a desk in an office all day, the 9-5 schedule isn’t for me. Every single day is something new, and a new challenge for me, it’s never ‘lather, rinse, repeat.’

Would you say this career is booming in our region?

I definitely think it’s easier here in Windsor now for anyone starting out in the trade than it was for me when I first started the process 7 years ago. Companies are so eager to hire good workers now. There’s a huge trades shortage and every company out there is hiring. The company I work for is extremely eager for more workers.

When I first started people were saying “Get into the trades- it’s going to be booming!” Well now it’s actually booming. We can all tell it will be for a while.

You can learn even more about Electricians through our detailed Career Profiles.

Are you a female working in the trades or hoping to? Looking for some advice from Women in the trade, or looking to mentor young girls? Join our Facebook Group: Windsor-Essex Women in Skilled Trades to get tips for the trades, advice, and answers to all the questions you’ve always wanted to ask!

If you work in a skilled trades position, and would be willing to be interviewed for a Workforce Profile, please email:

sfram@workforcewindsoressex.com